Maintenance factor

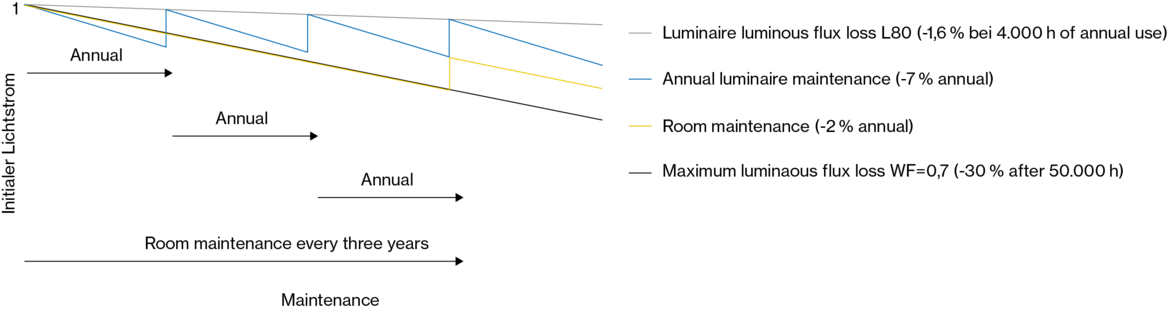

Lighting systems are subject to contamination and wear until the end of their useful life. A lighting system's maintenance factor indicates how much of the initial luminous flux remains available at the end of its service life. The maintenance factor must be determined by the planning lighting engineer and the new value of the luminous flux multiplied by it. This ensures that the specified light intensity remains at the end of the service life. The light intensity needed for a given work activity is set out by the EN 12464-1 International Lighting Standard. A lighting system's maintenance factor is composed of four factors.

1) Luminous flux maintenance factor or luminaire service life specification

... indicates the luminaire's luminous flux until at least the end of its service life. The useful life of a professional system is 50,000 hours. These 50,000 hours correspond, for example, to 12.5 years in an office or shopping centre at 4,000 hours' annual operating time. The industry standard is set for L80 luminaires after 50,000 hours. "L80" indicates that at least 80% of the initial luminous flux remains after 50,000 hours. Higher quality L90 luminaires still have at least 90% of the luminous flux after 50,000 hours and are therefore 12.5% more valuable. L80 luminaires' luminous flux maintenance factor is 0.8; that of L90 luminaires is 0.9.

2) Luminaire maintenance factor

... indicates the extent the luminaire's luminous flux decreases due to contamination. A cleaning schedule is established to minimise the drop in luminous flux due to contamination. The lighting engineer responsible lists this cleaning schedule in a maintenance plan. The lighting designer hands over the maintenance plan to the lighting installation's operator who guarantees the required luminous flux if it is executed correctly. The lighting designer determines the luminaire maintenance factor from tables set out in CIE 97-2005. Example: If in a clean environment, such as an office, the light-emitting surface is thoroughly cleaned once a year, the luminaire maintenance factor is: 0.93 (the luminous flux decreases by a maximum of 7% until cleaning).

3) Room maintenance factor

... indicates the extent the luminous flux decreases due to contamination of the ceiling and walls. In the case of a light calculation, reflection values are assumed for the surfaces bounding the room, which represent the new value. As the room is used, the reflectance value decreases until it is repainted. Example: If in a clean environment, such as an office, the walls are repainted every three years, the room maintenance factor is: 0.94 (the luminous flux decreases by a maximum of 6% until repainting).

4) Lamp survival factor

... indicates how the total failure of individual lamps is to be evaluated. Modern lighting systems exclusively use LED technology. It is assumed that any failed luminaires are quickly replaced. The lamp survival factor is a relic from the time of conventional lamps and can be assumed to be "1".

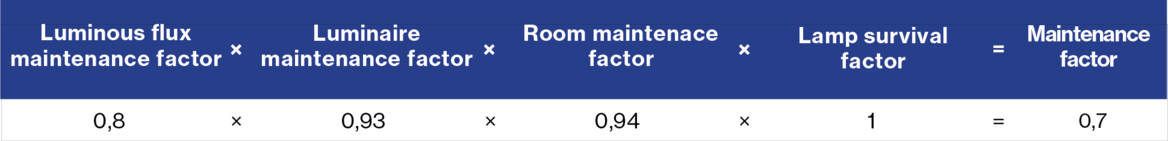

Example of a maintenance factor calculation:

Luminous flux maintenance factor x luminaire maintenance factor x room maintenance factor x lamp survival factor.

0.8 x 0.93 x 0.94 x 1 = WF = 0.7

Maintenance plan

The lighting designer shall submit the following maintenance plan to the lighting system operator: "The lighting system is designed for a clean environment, like an office. The prescribed light intensity level is ensured by thorough annual cleaning of the light-emitting surfaces. Furthermore, walls and ceilings must be repainted with pure white paint every three years. Failed luminaires are to be quickly replaced."

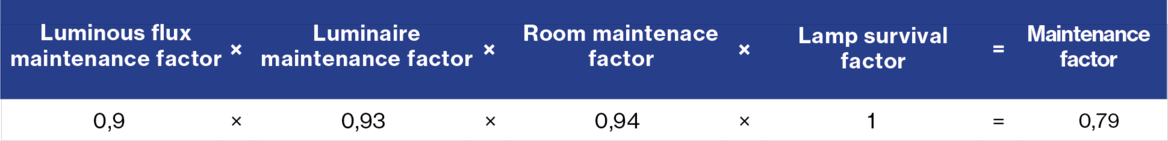

Comparison L80 vs. L90

L80 luminaires with a luminous flux maintenance factor of 0.8 achieve at best a lighting system maintenance factor of 0.7 for 50,000 hours. (Clean environment (office), luminaire cleaned annually, wall repainted every three years, failed luminaires replaced).

L90 luminaires (Clean environment (office), luminaire cleaned annually, wall repainted every three years, failed luminaires replaced). L90 luminaires have a maintenance factor of 0.79 and are 12.9% more efficient.

Zero maintenance

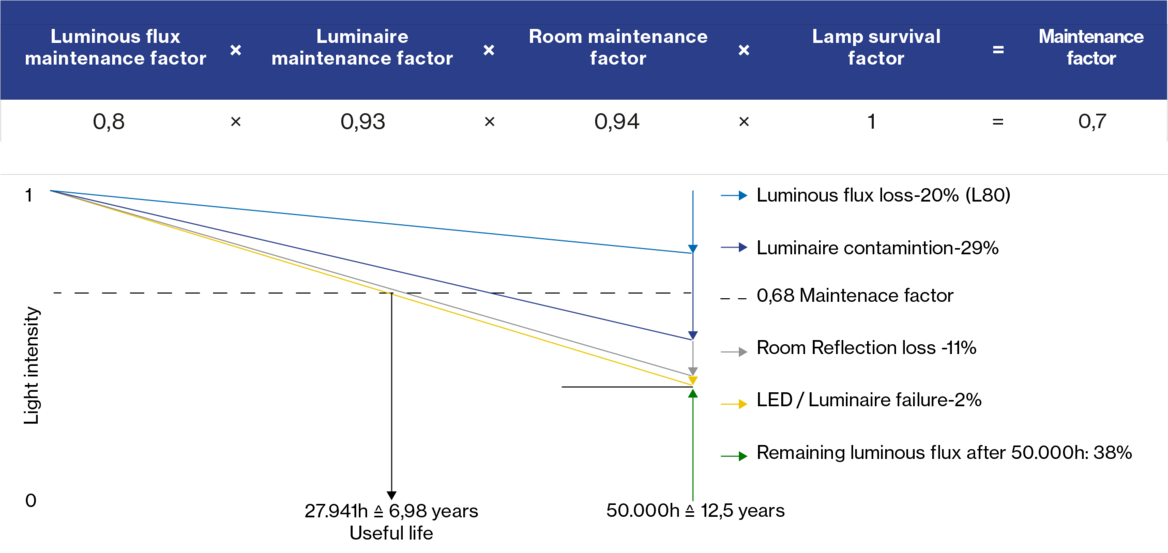

How does luminous flux behave if no maintenance is carried out?

With regular maintenance, we assume a maintenance factor of 0.68. If no maintenance is carried out, the illuminance falls below the minimum value after 27,947 hours. With 4,000 hours of annual use, the luminous flux needs to be corrected after 7 years.

Example

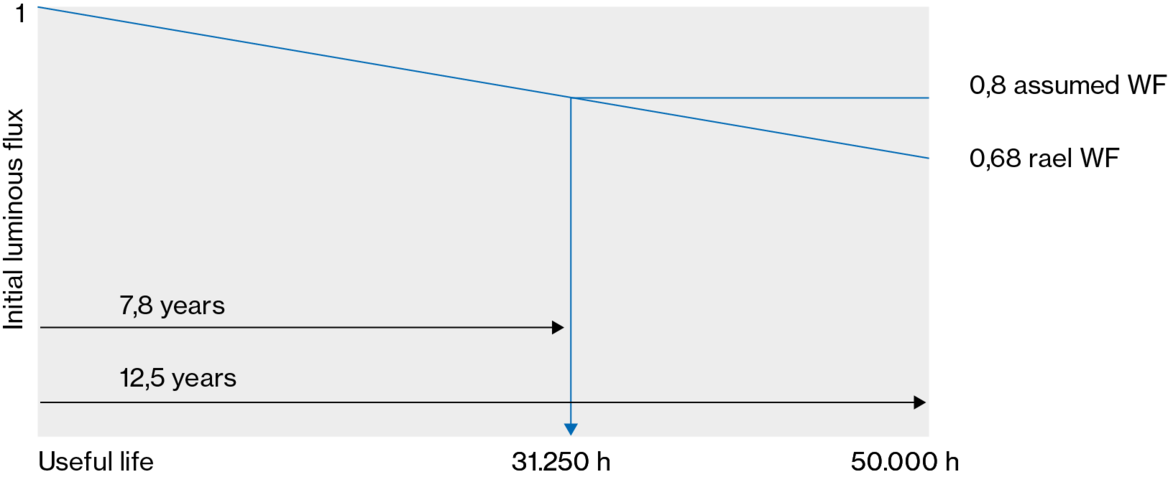

Use of MF 0.8 with L80 luminaires

Lighting designers sometimes make lighting calculations using 0.8, rather than the real maintenance factor of 0.68. This is done to keep the investment costs of the lighting system as low as possible. The lighting designer must correctly inform the system operator that the lighting system does not guarantee the required luminous flux for 50,000 hours, but only for 31,250 hours. Luminous flux reduction at (MF 0.8) 20% / Luminous flux reduction (at MF 0.68) 32% x rated life (20/32 x 50,000 = 31,250) Consequently, at 4,000 hours of annual use, the lighting system must be upgraded at 7.8 years, and not 12.5 years

Conclusion

The derivation of the maintenance factor must be documented and submitted to the plant operator together with the lighting calculation and the maintenance plan. Only if the maintenance factor is calculated conscientiously and maintenance is carried out can the light intensity be provided and a useful life of 50,000 hours achieved.